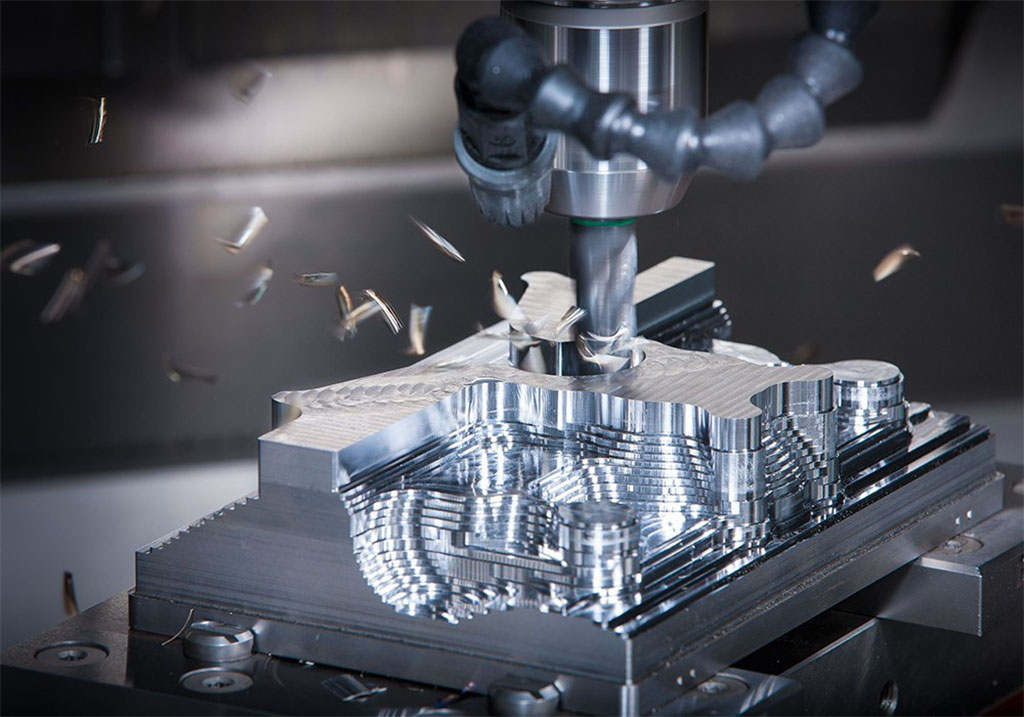

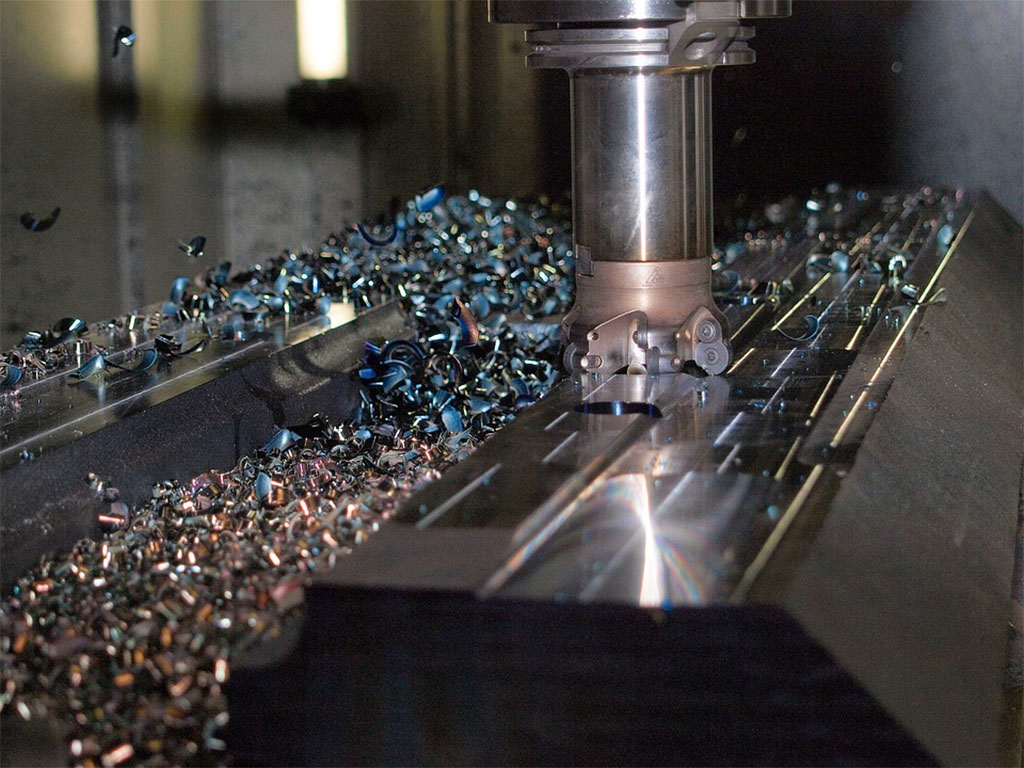

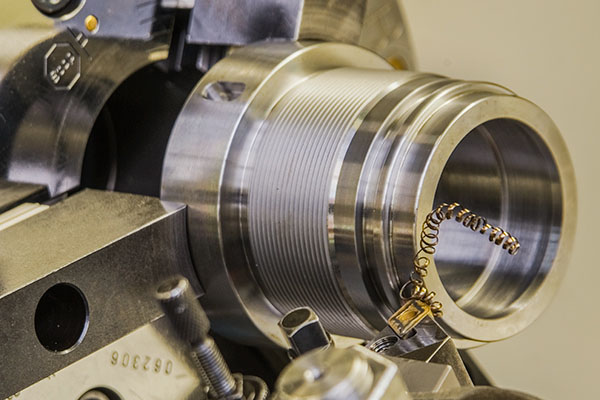

Does your metal part require additional protection or finishing? At Vanderscheuren nv we have over 65 years of experience in metalworking. We specialise in CNC turning, CNC milling, sheet metalworking, manual welding, robotic welding, hydraulic cylinders, and the assembly of all types of metal. We are also your one-stop-shop for surface treatments. We know the properties of each type of metal and determine which treatment or finish is needed according to the quality requirements. We outsource metal treatment to our preferred partners for a reliable result.

A selection of the available surface treatments for metal

For every surface treatment, we engage our preferred partners:

In the case of galvanisation or electrolytic galvanising, your product will undergo an electrolytic treatment producing an adhesive metal coating. The craftsman hangs the material on racks or places it in barrel tumblers and sets the correct parameters. The fully automatic machines then disinfect, pickle and coat the material with the desired metal coating. Depending on the material, requirements and application, the additional coating with zinc, nickel, aluminium, chromium or magnesium will provide improved corrosion resistance, electrical conductivity or wear resistance.

Anodising or eloxation is also an electrolytic surface treatment. The anodising process coats aluminium or titanium with an oxide layer. This protective coating improves corrosion resistance as well as wear resistance, resulting in a more beautiful surface.

Powder coating is an electrostatic surface treatment. The craftsman uses compressed air to spray powder paint particles having a negative charge onto the electrically grounded workpiece. Because the grounded workpiece attracts the powder, it temporarily “sticks”. The workpiece is then melted or baked in an oven at a temperature of 140° to 220°C. Due to the continuous heating, the powder particles become liquid, then viscous and finally harden to become solid. There is no overspray loss with powder coatings, as the back of the object also attracts powder particles.

Powder coating cannot be performed if the material is not heat-resistant or if the dimensions do not allow it. To paint your metal, we also use wet coating, known as spraying, preserving or coating. The metal is then coated with one or more coats of lacquer, which guarantees good corrosion resistance, a smooth end result and a long life. The wet coating of small metal parts (such as hinges, spools, rims and brake pads) is done on the wet coating line. Large parts are processed in a spray booth.

Phosphate coating is a chemical surface treatment that applies a layer of phosphate compounds to a metal surface. The item is cleaned and then heated to approximately 90°C in a bath containing primary phosphates such as iron, manganese or zinc. This creates an insoluble conversion layer, that provides greater corrosion protection in addition to ensuring better adhesion of the lacquer or varnish.

By hardening metal, we increase the wear resistance and hardness of the metal. We heat the alloy to a specific temperature and then cool it quickly, creating martensite. The result is an extremely hard material because of the internal stresses in the metal.

Do you have a different surface treatment in mind for your product?

The advantages of a surface treatment

Surface treatment provides your metal with added value:

- aesthetic finish (glass, matt, coloured or special effects)

- improved mechanical and physical properties

- improved electrical or thermal conductivity

- increased safety

- less maintenance

- cleaned metal surface

- better adhesion of paint or glue

- longer life

- protection against fire or slipping

- protection against external or harmful influences, such as corrosion or weather conditions

- aesthetic finish (glass, matt, coloured or special effects)

- improved mechanical and physical properties

- improved electrical or thermal conductivity

- increased safety

- less maintenance

- cleaned metal surface

- better adhesion of paint or glue

- longer life

- protection against fire or slipping

- protection against external or harmful influences, such as corrosion or weather conditions

Other metalworking techniques

Are you looking for more than a surface treatment of your metal? Thanks to our well-equipped workshop and our employees’ expertise, we are your preferred partner for specialised metalworking techniques:

Why you should outsource your surface treatment to us

At Vanderscheuren nv, we have been supplying SMEs and large companies with all-inclusive metal solutions since 1957. We aim to maintain long-lasting relations, thereby unburdening you of the entire metalworking. You provide us with your product idea, we advise you on the possibilities, potential obstacles and price guidelines to produce a feasible, practical and affordable product. We have a wide range of machinery and sophisticated machines, a customer service and quality department and a climate-controlled measurement chamber. Moreover, we have also obtained the ISO 9001 quality label. Our skilled professionals understand the requirements of your product and produce a custom high-quality solution.

Surface treatment of all types of metal

At Vanderscheuren you can request surface treatments of numerous types of metal:

- raw steel

- galvanised steel

- Corten steel

- aluminium

- Hardox®

- stainless steel

Various sheet metalworking techniques

Would you like to have your metal part processed by using a specific sheet metalworking technique? Are you not sure which technique is appropriate for your application? Our skilled professionals will gladly advise you on the possible sheet metalworking techniques that your product requires:

1. Barrell tumbling or deburring

Certain metalworking techniques leave residues such as sharp edges or irregularities on the material, for example during laser cutting. We barrel tumble the metal to make rough or sharp edges smooth. By barrelling metal, which is also called deburring or tensile grinding, we make it clean, beautiful, smooth and hand-friendly, we maintain the correct shape and we avoid delays in further processing. We place your part between the grinding stones in a vibrating barrel tumbler. Water and a cleaning agent (compound) are added to this, so that dirt, shavings and chips are removed. The vibration creates friction between the grinding stones and your metal part, eliminating any imperfections.

2. Shaking

We choose to shake the metal when rough deburring is required. We only place the parts in the drum, where they rub against each other and remove any burrs as a result of the vibration.

3. Polishing

In some applications, a rough metal surface can cause problems. It is more susceptible to corrosion and dirt adhesion. In that case, we can polish your metal part. During this polishing process, we gradually use finer grits. The metal surface is given a high-gloss finish that minimises friction with other parts, increasing sliding power. In most cases, a polished finish is chosen for aesthetic reasons.

4. Straightening

After welding or lasering long pieces, torsion may occur because of the generated heat. To make the metal flat again, we straighten it to be able to further process it.

5. Brushing

Brushing or satin finishing is a sheet metalworking technique that we use to give your metal a matt/gloss line structure. This makes the material less susceptible to scratching and scratches become less visible. We also use brushing or satin finishing to remove damage and colour changes.