Are you a product or machine builder and do you need a specific metal part? No matter how compact or complex your design , Vanderscheuren nv can process it for you. We can work with all types of metal and have sophisticated machines for CNC turning, CNC milling, sheet metalworking, manual welding, robotic welding, hydraulic cylinders and assembly work. Does your product also need a surface treatment?We will gladly take care of this for you.

Maximum dimensions for CNC turning at Vanderscheuren nv

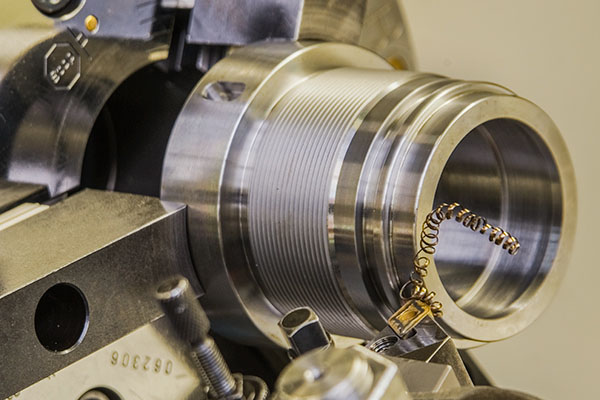

We can CNC turn metal with diameters ranging from 4 mm to 800 mm and lengths of up to 1400 mm.

The advantages of CNC turning

CNC turning has major advantages:

- high level of precision (perfect curved surfaces, notches and grooves)

- minimal risk of errors

- short time to machine

- consistent quality

- prototypes and serial production at high speed

- simple and more complex parts

- of various types of metal (steel, galvanised steel, Corten steel, aluminium, Hardox®, stainless steel and PVC)

- high level of precision (perfect curved surfaces, notches and grooves)

- minimal risk of errors

- short time to machine

- consistent quality

- prototypes and serial production at high speed

- simple and more complex parts

- of various types of metal (steel, galvanised steel, Corten steel, aluminium, Hardox®, stainless steel and PVC)

CNC turning for a wide range of industries

CNC turning offers numerous advantages, which makes it an interesting option for numerous industries:

Other metalworking techniques

Thanks to our fully equipped workshop and our skilled employees, we are able to perform all metalworking processes:

Vanderscheuren nv, an expert in metalworking

Vanderscheuren nv is a major player in the metalworking industry, with over 65 years of expertise in this field. Over the years, we have established numerous partnerships, providing our customers with custom, all-inclusive metal solutions. Our skilled employees think along with you, looking at how they can produce your product in a feasible, practical and affordable way.

We hold the ISO 9001 quality label and have a dedicated quality control department which is responsible for first unit measurements. We also have a climate-controlled measurement chamber with the newest measuring equipment, a customer service department and a wide range of machinery.

What is CNC turning?

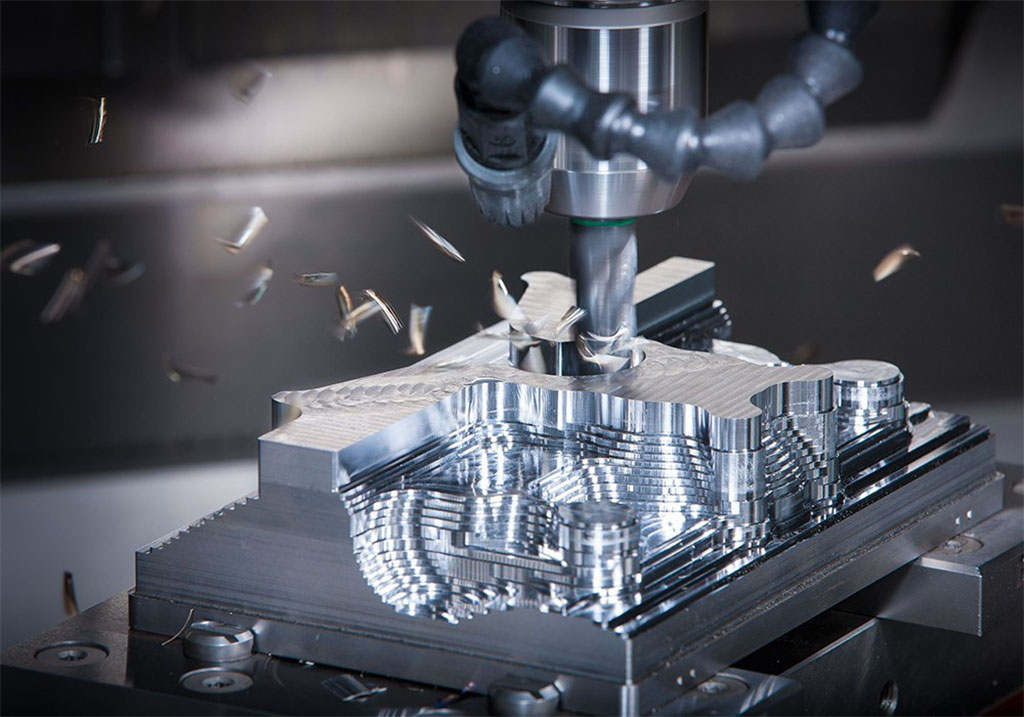

CNC stands for “Computer Numerical Control” and refers to the CNC machines that are used to process computer-controlled materials and semi-finished products. The machines can be programmed, which means that they can endlessly repeat processes with micro precision. We process piecework as well as large series, always obtaining the exact same product.

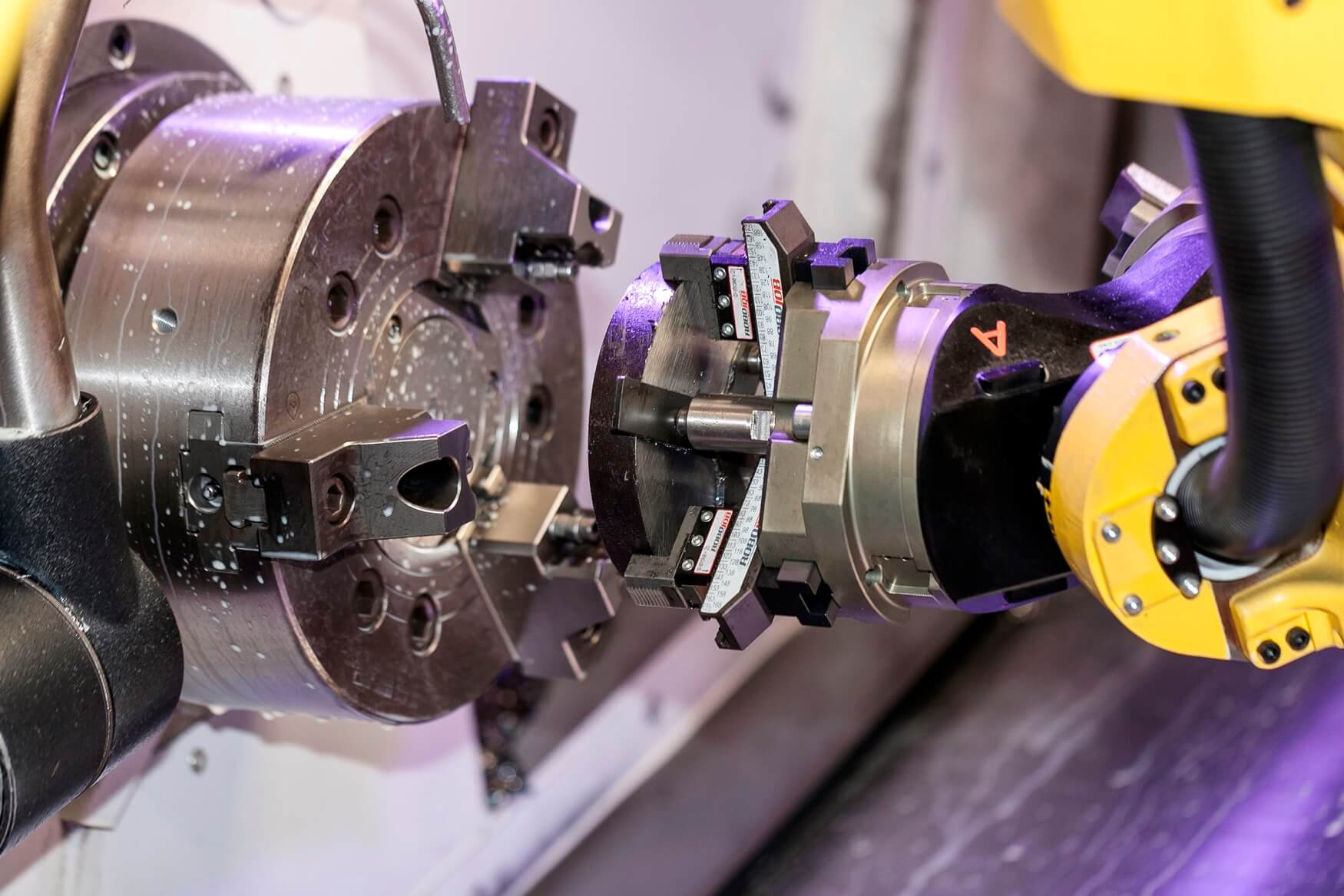

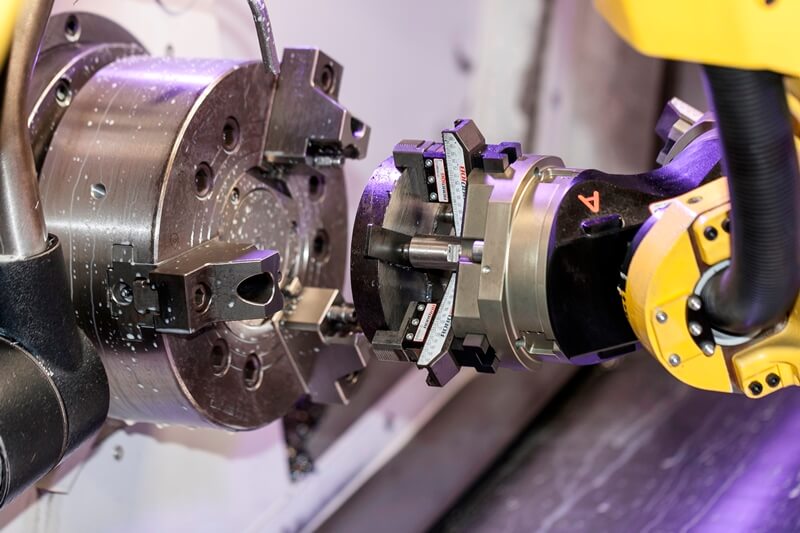

CNC machines are used for machining processes, such as CNC turning and CNC milling, where parts of the metal are removed. In CNC turning, the metal to be machined (the workpiece) is secured with the chuck of a CNC lathe or turning centre and is rotated at high speed. The cutting tool is pushed against the material in a linear and transverse direction along the X and Z axis. Chips are removed from the metal, producing the desired cylindrical or conical shape.

CNC turning with CAD/CAM software

We use CAD/CAM-software to CNC turn your product or machine part. A computer system enables us to digitally develop and shape your metal part, resulting in a CAD design. We then manufacture or produce the product by using software on a computer, the CAD system. A machine code indicates how the CNC turning centre must position the product, how and where it needs to be processed and at what speed this must be done.

Some possibilities of CNC turning centres

1. Horizontal CNC turning

Horizontal CNC turning centres are the most common machines. This turning centre holds the workpiece in a side grip, working the horizontal axis. The cutting tools and the workpiece remain stationary while the chuck rotates on the horizontal axis.

2. Vertical CNC turning

The vertical CNC turning centre subtracts the bottom of the workpiece and then flips it over.

3. Horizontal turning centre

A horizontal turning centre is a closed-loop CNC turning machine. The machine can drill and mill, and may be fitted with conveyor belts, in addition to using coolants or cutting fluids.

4. Vertical turning centre

Combined CNC milling and turning machines significantly reduce production time. They can perform 4 complex operations simultaneously without having to transfer the product to another machine.

5. Dual spindle lathe

The dual spindle lathe integrates two lathes into one single tool and has two spindles. This lathe is perfectly suited for mass production.

6. Turret tooling

In turret tooling the cutting tools are enclosed in a rotating, indexable tool holder. This is done with single and twin-turret lathes.

7. Gang tooling

In gang tooling the cutting tools are aligned in the lathe.

8. Milling processes

We also perform various milling processes on the CNC lathe with powered tools, such as key slots.